Product Overview

In recent years, metallurgists have advanced stainless steel technology with the development of superior grades like Duplex (2205). Compared to the widely used grade 316, Duplex steel contains higher levels of chromium, nickel, molybdenum, and nitrogen. This composition enhances its resistance to pitting and crevice corrosion, particularly in aggressive seawater environments. Consequently, 2205 stainless steel emerges as a superior choice over 316 and 316L for such demanding water conditions.

Benefits:

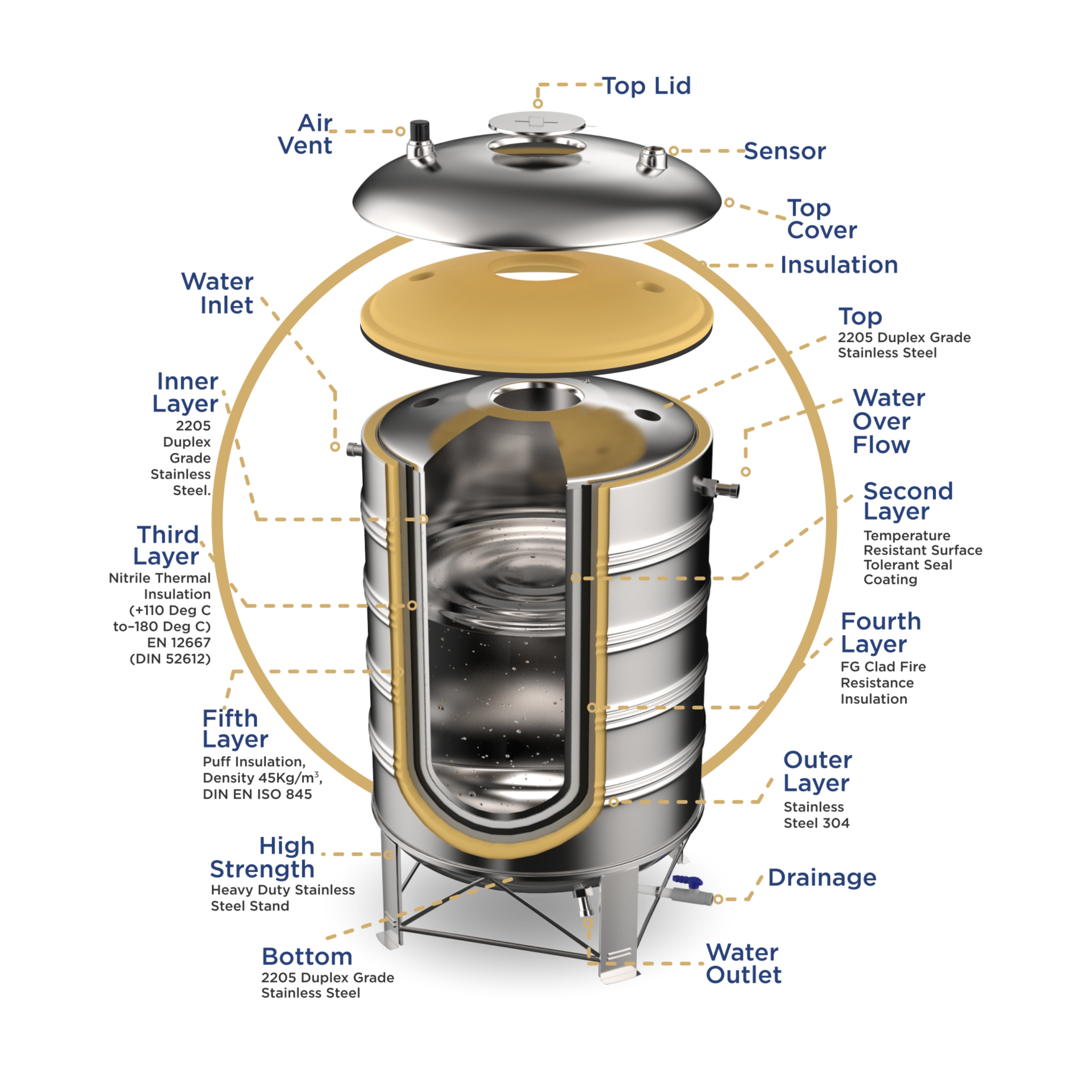

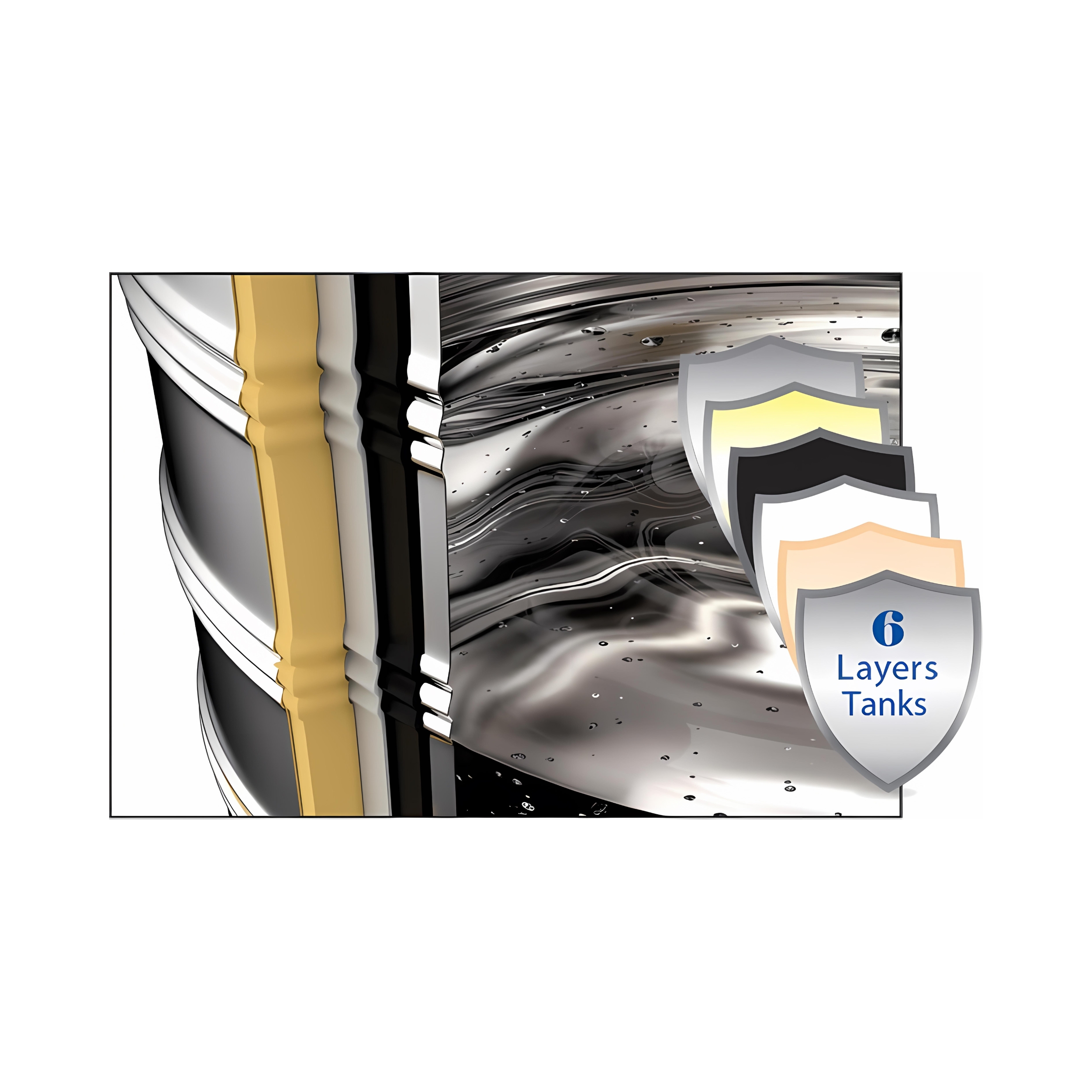

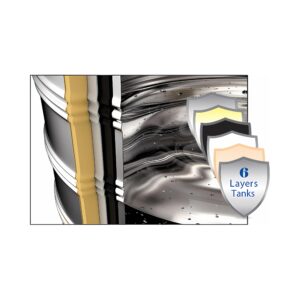

Six Layer Technology

Our innovative Six Layer Technology incorporates high-grade Class-O Nitrile Insulation and FGClad Fire resistance insulation, sourced from Italy. Additionally, it features a minimum of 50 mm and a maximum of 100 mm of high-grade CFC/HCFC-free polyurethane PU rigid foam insulation.

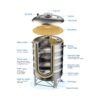

Inner Tank

The inner tank of Tropinox tanks boasts an ultra-smooth, non-corrugated surface that effectively prevents lime scale deposits. Its all-welded construction guarantees consistent efficiency and performance over time.

High Corrosion Resistance

Duplex stainless steel offers remarkable strength and exceptional resistance to stress corrosion cracking in various environments, including general aqueous corrosion and chloride stress corrosion.

- Thickness: Tropinox tanks are pressurized with a stainless steel thickness of 1.5 mm, which is approximately 80% thicker than other manufacturers offering tanks of similar capacities and dimensions.

- Universally Suitable: For customers facing challenges with harsh water corrosivity, such as pH levels, sulphates, chloride, hardness, conductivity, total dissolved solids (TDS), iron content, and ionic strength, Duplex Stainless Steel emerges as the optimal choice.

- Chromium Oxide Layer: In 2205 grade stainless steel, the 22% chromium content reacts with oxygen in the air and water to form a protective passive layer of chromium oxide. This layer serves as a barrier, preventing corrosion when exposed to dissolved oxygen and other aggressive elements commonly found in potable water.

Water Level Controller

Our tanks are equipped with an automatic water level controller to prevent water from exceeding the tank’s capacity.

Customized Stainless Steel Fittings

Tropinox Tanks offer a variety of fittings, with standard sizes available in 1″, 1.5″, and 2″. Additionally, larger sizes and custom configurations can be accommodated upon request, providing optimal options for manifold connections.

Big Manhole

The cap hole is generously sized to facilitate easy inspection, maintenance, and upkeep of the tank.

Quality Control & Testing

Throughout the manufacturing process, rigorous quality checks are conducted on all tanks and vessels. Additionally, an overall test is included as part of the Factory Acceptance Tests (FAT) procedures, with relevant documentation forming part of the FAT protocols.

Pressure Equipment Directive

Our pressurized tanks are designed and manufactured in compliance with the requirements of European pressure equipment directives.

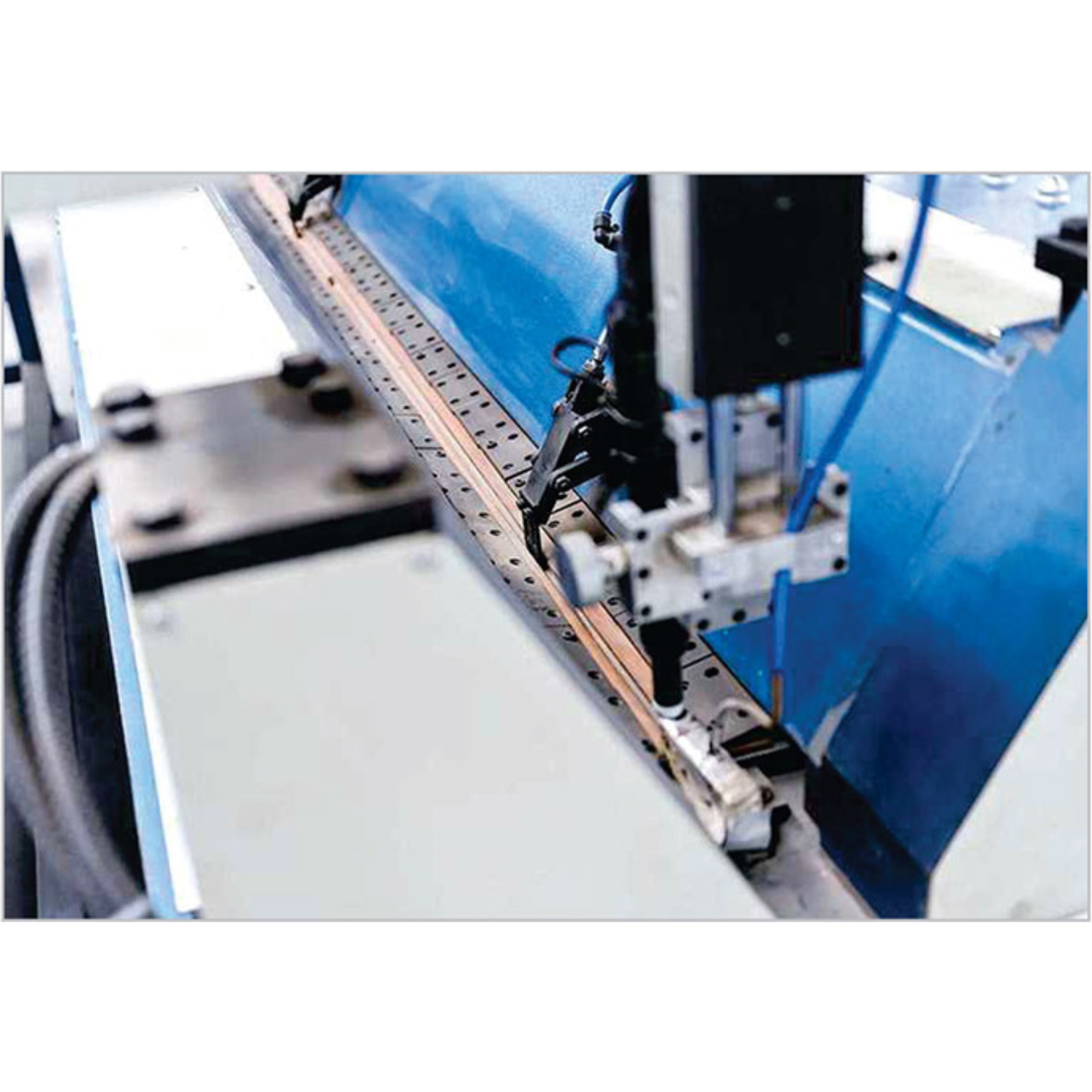

Weld Quality

Utilizing advanced automated welding techniques, our tanks are Pulse Tig welded to ensure precise welding with a concentrated heat source.